Description

Benka Beekeeping – Automatic Steam Wax Separator

Developed by Benka Beekeeping, the Automatic Steam Wax Separator is an innovative piece of beekeeping equipment that combines multiple functions into a single modular design. This versatile machine can be used as a wax separator, honey extractor, creamed honey mixer, honey melting and settling tank, and syrup blender. Thanks to its modular structure, the internal components can be easily replaced to instantly switch between different functions.

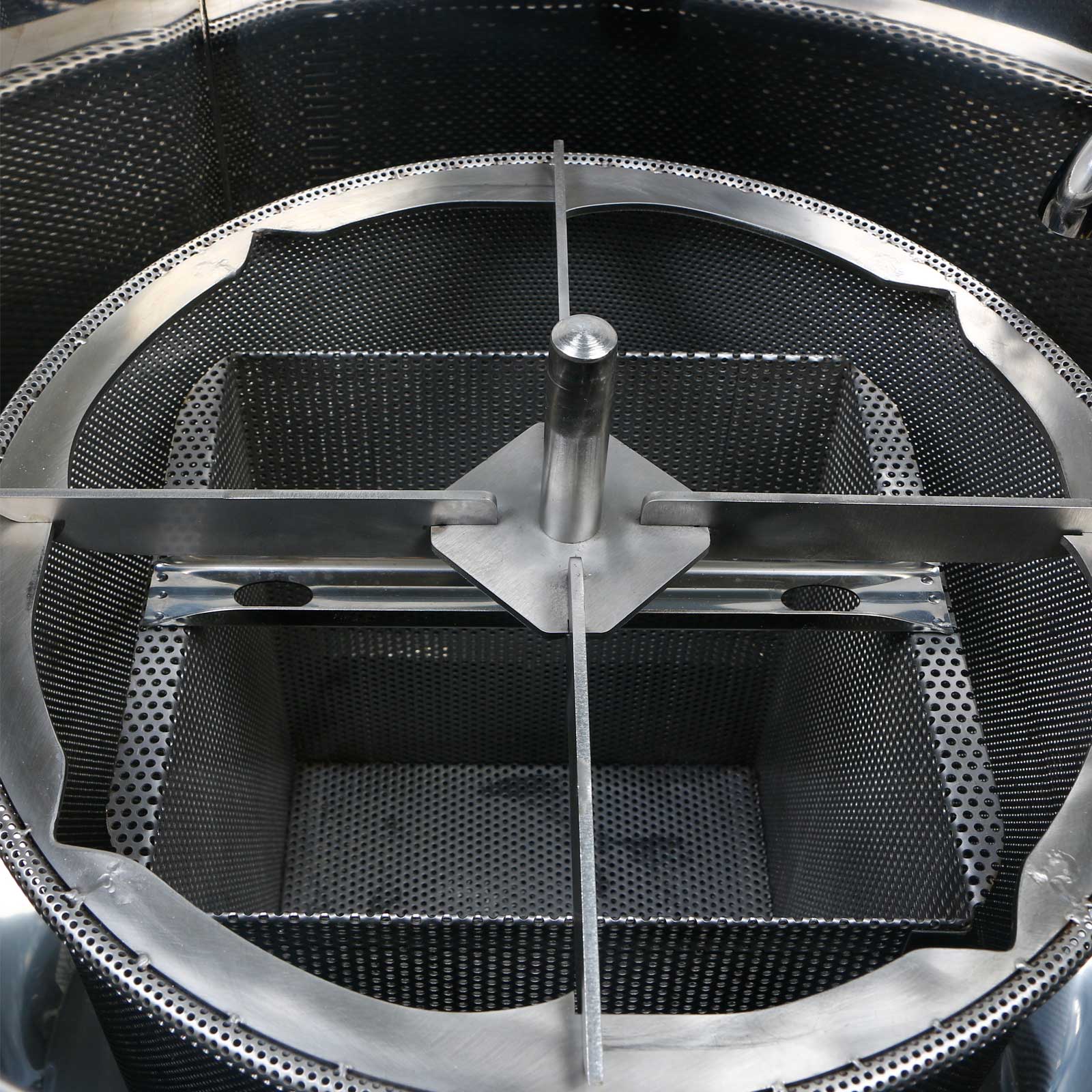

Using the Device as a Wax Separator

A water tank located at the bottom of the device produces steam via a 3000W heater.

The steam is directed into the upper chamber through a special hose, raising the internal temperature of the tank.

Powered by the lower motor, the separator basket rotates, and the centrifugal force separates the wax and comb debris from the honey.

The melted wax can be conveniently collected through a tap located on the front of the machine.

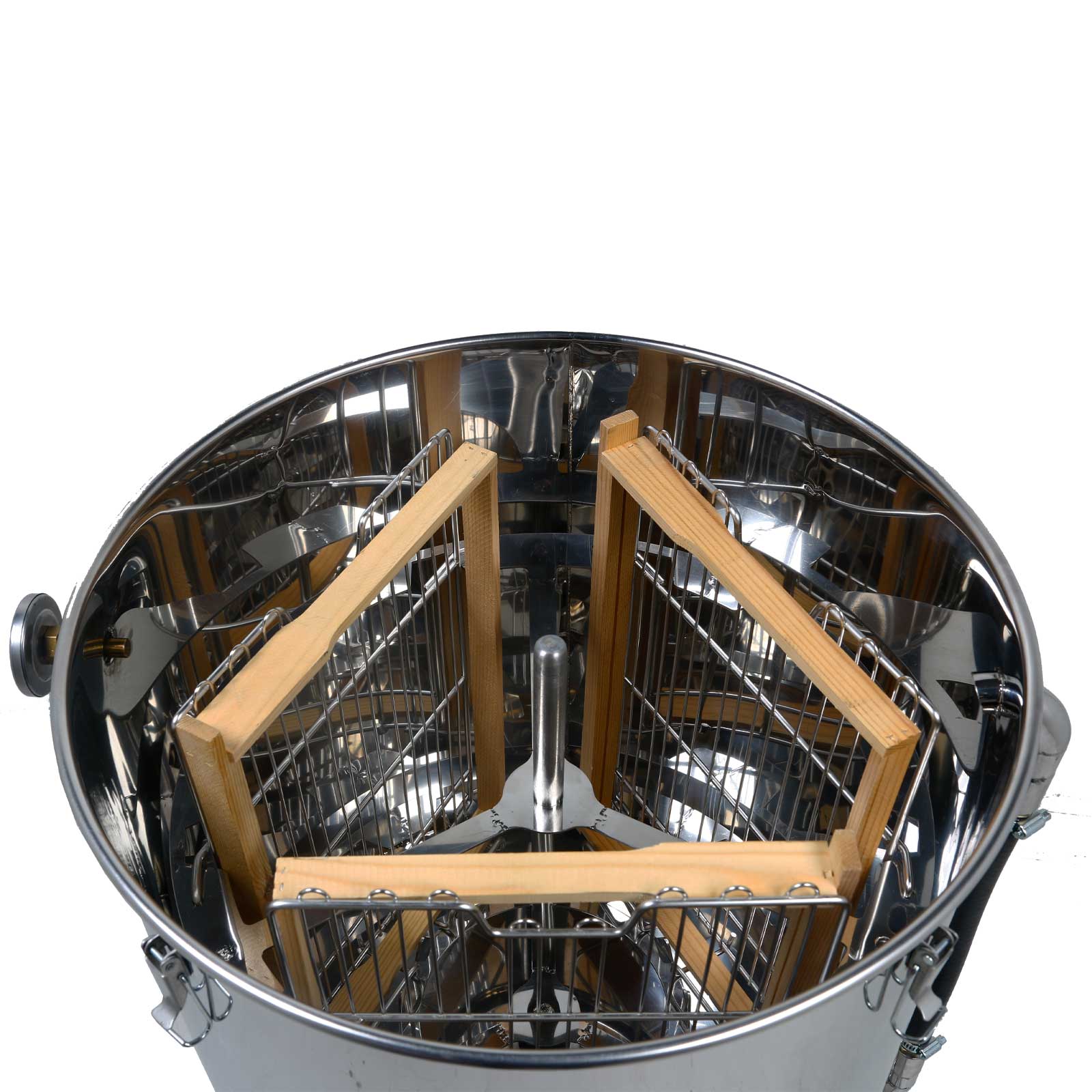

Using the Device as a Honey Extractor

The internal components can be removed without tools and replaced with a honey extractor basket.

It comes standard with a radial basket that can hold 3 to 12 frames and is also compatible with a 4-frame Langstroth basket.

The speed can be adjusted via the potentiometer at the rear, allowing gentle extraction without damaging the combs.

Using the Device as a Creamed Honey Mixer

To produce creamed honey, a mixing blade must be installed.

A 250W AC motor ensures thorough mixing to achieve the desired consistency.

The steam hose can be removed to prevent steam from entering during this process.

Speed can be adjusted according to need using the potentiometer.

Using the Device as a Syrup Blender

To mix syrup into a homogeneous solution, the mixer blade should be installed.

If heating is preferred, the water tank should be filled, and the steam hose should be disabled.

Speed can be adjusted during the mixing process.

Using the Device as a Honey Melting and Settling Tank

All internal parts should be removed before use in this mode.

If the heater is used, enough water should be added to the tank, and the steam hose should be closed off.

Honey should be melted and allowed to settle at a stable temperature. A maximum of 35–40°C is recommended to prevent an increase in HMF levels, which could negatively affect honey quality.

Easy and Hygienic Cleaning

The steam generator at the base provides high-temperature cleaning.

For cleaning, fill the water tank with enough water and activate the heater.

The temperature reaches 90–100°C within approximately 20 minutes, and within 30 minutes, all wax, honey, and sugar residues are dissolved and cleaned.

Finally, the machine should be cleaned with food-safe cleaning agents that won’t damage stainless steel, then rinsed and dried.

Key Advantages

✔ Compact and portable design

✔ Multi-purpose use with easy conversion

✔ Five different functions: wax separation, honey extraction, creamed honey mixing, syrup blending, honey melting and settling

✔ Excellent value for money

✔ Durable and long-lasting construction

Who Is This Product For?

This machine is ideal for beekeepers who prioritize wax recycling. Reusing wax reduces production costs and supports sustainable practices.

Additionally, the unit is compatible with Benka’s Frame Washing System, allowing direct placement of the square wax basket into the device—eliminating the need for wax transfer and streamlining the workflow.

Reviews

There are no reviews yet.